Description

The TP4, TP6 and TP12 drawing machines were designed for drawing gold and silver wire.

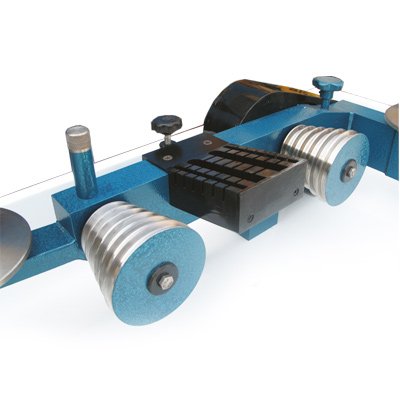

The drawing process takes place through a series of drawplates with calibrated holes that decreasing bt 0.1 mm in diameter (for wires with a diameter of 2.5 > 0.5 mm) and 0.05 in diameter (for wires with a diameter of 0.5 > 0.3 mm).

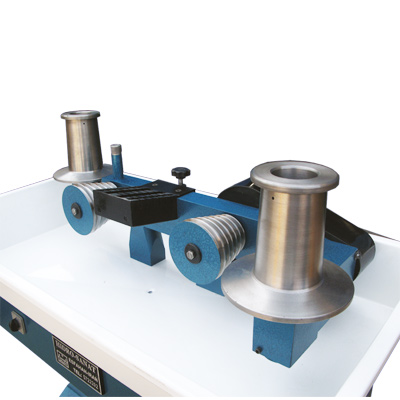

The machine is composed by a sturdy metal frame that holds the motor, transmission, the cooling liquid tank, the unwinding reel, the motorised winding reel with adjustable clutch controlled by a handwheel (to allow the machine to start gradually to prevent the wire from breaking), the drawplate support, an electrical control panel and a protective casing for moving parts.

Both reels are interchangeable. The top cover can be removed to rapidly extract the roll of finished wire.

The machine also has a separate cooling circuit for lubricating the drawing plates with emulsified oil. A special filter applied to the scavenge pipe permits recovery of metal filings. The tank can be removed to simplify cleaning procedures. The machine also has safety guards and devices.

Specification

Number of passages

12

Drawing speed

46-92 m/min

Drawing size

ø2,5÷0,3mm

Absorbed power

4,5 kW

Power supply

400V~3,50/60Hz

Weight

400Kg

Voltage

220V/50-60Hz

Dimension

118x63x120(h)

The TP4, TP6 and TP12 drawing machines were designed for drawing gold and silver wire.

The drawing process takes place through a series of drawplates with calibrated holes that decreasing bt 0.1 mm in diameter (for wires with a diameter of 2.5 > 0.5 mm) and 0.05 in diameter (for wires with a diameter of 0.5 > 0.3 mm).

The machine is composed by a sturdy metal frame that holds the motor, transmission, the cooling liquid tank, the unwinding reel, the motorised winding reel with adjustable clutch controlled by a handwheel (to allow the machine to start gradually to prevent the wire from breaking), the drawplate support, an electrical control panel and a protective casing for moving parts.

Both reels are interchangeable. The top cover can be removed to rapidly extract the roll of finished wire.

The machine also has a separate cooling circuit for lubricating the drawing plates with emulsified oil. A special filter applied to the scavenge pipe permits recovery of metal filings. The tank can be removed to simplify cleaning procedures. The machine also has safety guards and devices.

Number of passages

12

Drawing speed

46-92 m/min

Drawing size

ø2,5÷0,3mm

Absorbed power

4,5 kW

Power supply

400V~3,50/60Hz

Weight

400Kg

Voltage

220V/50-60Hz

Dimension

118x63x120(h)