Description

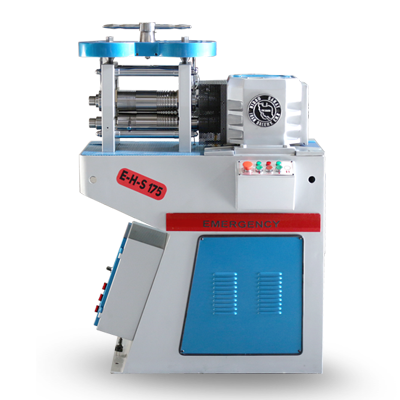

Field of application: These model of rolling mills is ideal for small workshops as well as industrial production (continues and non-continues production)

Type: the configurations are plate roughing mills or wire roughing mills. The rolling mills are mainly used for plate & wire rough-rolling and finishing or bar rough rolling and finishing

.

Rolling mills for plate and WIRE EHS lS160- EHS IS175

And EHS IS200

Structure

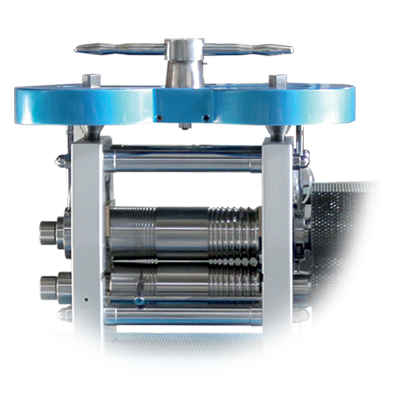

Cylinders: the cylinders are made of special alloy steel with a grinded surface hardness 64 HRC (plate cylinders), 61 HRC (bar cylinders). On request it is possible to supply plate cylinders with mirror finish, hard chromium plating, internal water-cooling system with rotating joints.

Cylinders bearings: the bearings are mounted on mobile guides, they are heavy duty bronze plain bearings and are provided with automatic closed circuit pressure lubrication with oil recovery and water-cooled circuit.

Cylinders displacement: manual displacement by hand wheel. Cylinders drive: by means of mechanical homo-kinetic universal joint.

Reduction gear unit: the rolling mills have a reduction unit made of helicoidally steel gears with oil bath lubrication. The electric motor drives the reduction gear through mechanical joint.

Drive: the rolling mills are driven by a one-speed electric motor. On board there is a control panel that includes all devices of maneuver and control. On request a drive with electronic variable speed through inverter sectorial is available.

Reels: available, on request: reversible hydrostatic strip winder; horizontal motorized wire winder; horizontal idle de coiler for strip. vertical motorized wire winder; de colier for wire.

Safety devices: safety devices are provided (in conformity with the international laws ), including: mechanical grids for cylinders, pneumatic barriers for emergency stop. Optional accessories: the rolling mills can also be equipped with a series of accessories chosen according to production needs. We can provide spray lubrication system for plate.

Specification

Single Head Rolling Mill175

-----------------------------------------------------------------------

Cylinder width

240mm

Cylinder diameter

90mm

Rolling speed

7.3-14.6m/min

Motor power

2.2-4.8kw

Voltage

220/380V - 50/60Hz

Width

950mm

Depth

500mm

Height

1450

Weight

450kg

Single Head Rolling Mill160

-----------------------------------------------------------------------

Cylinder width

240mm

Cylinder diameter

84mm

Rolling speed

7.3-14.6m/min

Motor power

2.2-4.8kw

Voltage

220/380V - 50/60Hz

Width

950mm

Depth

500mm

Height

1450

Weight

400kg

Field of application: These model of rolling mills is ideal for small workshops as well as industrial production (continues and non-continues production)

Type: the configurations are plate roughing mills or wire roughing mills. The rolling mills are mainly used for plate & wire rough-rolling and finishing or bar rough rolling and finishing

.

Rolling mills for plate and WIRE EHS lS160- EHS IS175

And EHS IS200

Structure

Cylinders: the cylinders are made of special alloy steel with a grinded surface hardness 64 HRC (plate cylinders), 61 HRC (bar cylinders). On request it is possible to supply plate cylinders with mirror finish, hard chromium plating, internal water-cooling system with rotating joints.

Cylinders bearings: the bearings are mounted on mobile guides, they are heavy duty bronze plain bearings and are provided with automatic closed circuit pressure lubrication with oil recovery and water-cooled circuit.

Cylinders displacement: manual displacement by hand wheel. Cylinders drive: by means of mechanical homo-kinetic universal joint.

Reduction gear unit: the rolling mills have a reduction unit made of helicoidally steel gears with oil bath lubrication. The electric motor drives the reduction gear through mechanical joint.

Drive: the rolling mills are driven by a one-speed electric motor. On board there is a control panel that includes all devices of maneuver and control. On request a drive with electronic variable speed through inverter sectorial is available.

Reels: available, on request: reversible hydrostatic strip winder; horizontal motorized wire winder; horizontal idle de coiler for strip. vertical motorized wire winder; de colier for wire.

Safety devices: safety devices are provided (in conformity with the international laws ), including: mechanical grids for cylinders, pneumatic barriers for emergency stop. Optional accessories: the rolling mills can also be equipped with a series of accessories chosen according to production needs. We can provide spray lubrication system for plate.

Single Head Rolling Mill175

-----------------------------------------------------------------------

Cylinder width

240mm

Cylinder diameter

90mm

Rolling speed

7.3-14.6m/min

Motor power

2.2-4.8kw

Voltage

220/380V - 50/60Hz

Width

950mm

Depth

500mm

Height

1450

Weight

450kg

Single Head Rolling Mill160

-----------------------------------------------------------------------

Cylinder width

240mm

Cylinder diameter

84mm

Rolling speed

7.3-14.6m/min

Motor power

2.2-4.8kw

Voltage

220/380V - 50/60Hz

Width

950mm

Depth

500mm

Height

1450

Weight

400kg