Description

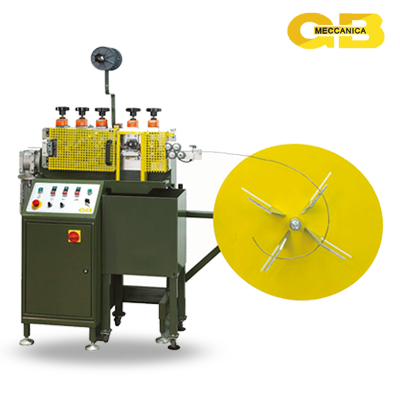

Hollow wire machine to manufacture empty chain. Tombak / iron diameter 5mm or 8mm. Strip thickness from 0.20 to 0.80 mm.

Once the tombac, supplied to the machine in skeins, has been automatically drawn inside, it straightens it, by passing it through a group of wheels, and by means of mills forms 2 channels above and one underneath. A jet of air removes any eventual impurities.

At the same time, from the opposite side, the machine draws the goldplate or other material, and winds around the tombac grasping it in the 2 higher channels and inserts the soldering wire in the lower one. During exit a die with wheels gives the pipe a square shape, therefore semplifying the successive processes of lamination, optimizing the quality of the finished product.

Consequently using this processthe work of the operator is reduced to a simple and rapid insertion of the strip in a special guide at the beginning of the procedure. Further more the presence of the mills with replaceable widia inserts, lets the machine to work at an elevated speed and with a major resistance to wear, not only tombac but materials such as iron or alluminium.

Further qualities of this machine consist in the absence of waste and the possibility of working with plates of various and unlimited lengths.

Specification

DIMENSIONS

2150x810; H=1700

WEIGHT

500 Kg

WORK SPEED

up to 0,4 m/min

Hollow wire machine to manufacture empty chain. Tombak / iron diameter 5mm or 8mm. Strip thickness from 0.20 to 0.80 mm.

Once the tombac, supplied to the machine in skeins, has been automatically drawn inside, it straightens it, by passing it through a group of wheels, and by means of mills forms 2 channels above and one underneath. A jet of air removes any eventual impurities.

At the same time, from the opposite side, the machine draws the goldplate or other material, and winds around the tombac grasping it in the 2 higher channels and inserts the soldering wire in the lower one. During exit a die with wheels gives the pipe a square shape, therefore semplifying the successive processes of lamination, optimizing the quality of the finished product.

Consequently using this processthe work of the operator is reduced to a simple and rapid insertion of the strip in a special guide at the beginning of the procedure. Further more the presence of the mills with replaceable widia inserts, lets the machine to work at an elevated speed and with a major resistance to wear, not only tombac but materials such as iron or alluminium.

Further qualities of this machine consist in the absence of waste and the possibility of working with plates of various and unlimited lengths.

DIMENSIONS

2150x810; H=1700

WEIGHT

500 Kg

WORK SPEED

up to 0,4 m/min